HIGH-TECH EQUIPMENT

FRAUNHOFER IGCV CONTINUOUS FIBER TAILORING (CFT)

PROTOTYPE MACHINE

- Efficient production of highly drapeable 2D stacks

- Materials: 50k rovings, thermoplastic binder veil

- Layer fixation: infrared activation of binder systems

- Variable number of rovings: up to 30

- Individual cut and feed

- Max. layer width: 600 mm

FIBERFORGE RELAY 2000 TAPELAYING

- Materials: thermoplastic tapes based on glass or/and carbon fibers

- Material fixation: ultrasonic spot welding

- Number of tapes: 2

- Flexible tape width range: 50 mm – 150 mm

- Max. part size: 2 x 2 m²

- Part geometries: 2D

BROETJE-AUTOMATION

STAXX COMPACT 1700

- Composite materials: thermoplastic and thermoset

- Heating systems for material fixation: infrared or diode laser

- Number of tows / tapes: 16

- Width of the material: ½’’ thermoplastic and thermoset

- Max. part size: 1,4 x 1,1 m²

- Part geometries: 2 – 2,5D

COMPOSITENCE FIBER PLACEMENT TECHNOLOGY

- Composite materials: thermoplastic, thermoset, dry fiber tapes

- Material fixation: edge fixation, infrared or laser

- Number of tows / tapes: 16 x 12 mm /

4 x 46 mm - Width of the material: 12 mm – thermoplastic and thermoset

46 mm – dry fiber tape - Max. part size: 2 x 2 m² – robot based system, 2,7 x 2 m² – linear axis system

- Part geometries: 2 – 2,5D

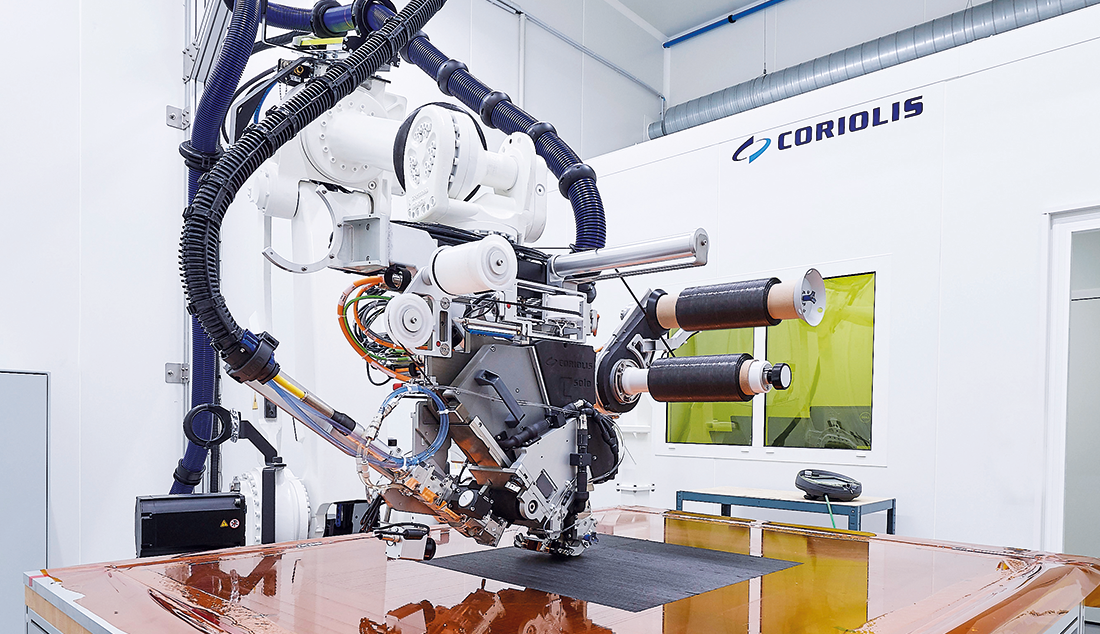

CORIOLIS C1

- Part geometries: 2D – highly complex 3D

- Machine type: robot based system

- CFRP material: thermoplastic, thermoset and dry fibers

- Heating systems for material fixation: IR or diode laser

- Head configuration: 8 tows / tapes

- Width of the material: ¼’’

- Max. part size: length 7 m, diameter 3 m

CORIOLIS Csolo

- Part geometries: 2D – 3D

- Machine type: robot-based-system

- CFRP material: thermoplastic, thermoset and dry fibers

- Heating systems for material fixation: IR or diode laser

- Head configuration: single tow / tape

- Width of material: ¼” – 1½”

- Max. part size: length 3 m; width 1,3 m

CEVOTEC SAMBA PRO

- Available for projects at FPC

- Configuration with 10 cooperating

robot axes and Scara fast picker - Max. part size: length 1,2 m, diameter

- Heating systems for material fixation: IR or diode laser

- Tape width: 12,5 mm (1/2″) – 50 mm (∼2″)

- Patch length: 50 – 200 mm

- Cutting system: fiber laser with ultra-high precision scanner

- Form-adaptive, customizable patch gripper in different sizes

The FPC Fiber Placement Center is a cooperation between

SGL Carbon, Fraunhofer IGCV, Broetje-Automation, Cevotec, Compositence and Coriolis Composites.

SGL Carbon, Fraunhofer IGCV, Broetje-Automation, Cevotec, Compositence and Coriolis Composites.

JOINT EXPERTISE

Fiber Placement Center

Werner-von-Siemens-Str. 18

86405 Meitingen / Germany

info@fiberplacementcenter.com

Werner-von-Siemens-Str. 18

86405 Meitingen / Germany

info@fiberplacementcenter.com

+49 8271 833460

Impressum

Impressum